Data sheet

Description: one-piece tanks with separated covering, perfect hydraulic tightness, to be placed in ground, maximum soil overload: 50 cm, (including pavement) with a calculated distributed live load of 2000 daN/sqm. Tanks are complete of N°1 inspection opening. Possible standard holes.

On demand:

- INOX AISI 304 flanges and sleeves sealed to perfect hydraulic tightness;

- PVC coupling sealed to perfect hydraulic tightness.

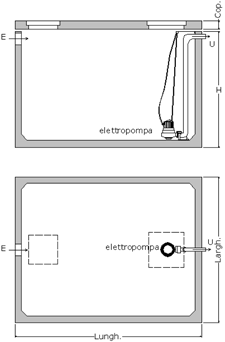

Simple parallelepiped tanks

Simple parallelepiped tanks

Tanks sizes

(standard production in cms)

Length | Width | H | Cov. | S. Volume | Weight |

(max) | (min) | (cu.m.) | (daN) | ||

| 150 | 105 | 180 | 20 | 2,05 | 2.758 |

| 160 | 130 | 200 | 20 | 3,06 | 3.802 |

| 200 | 150 | 220 | 20 | 5,10 | 5.241 |

| 250 | 210 | 250 | 20 | 10,31 | 9.660 |

| 320 | 250 | 250 | 20 | 16,00 | 13.995 |

Tanks can also be placed coupled, series or parallel, by planning specific connections.

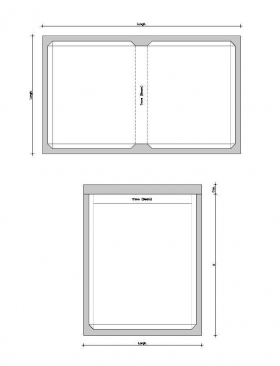

Ribbed parallelepiped tanks

Ribbed parallelepiped tanks

Tanks sizes

(standard production in cms)

Length | Width | H | Cov. | S. Volume | Weight |

(max) | (min) | (cu.m.) | (daN) | ||

| 420 | 250 | 300 | 20 | 25,62 | 19.955 |

| 520 | 250 | 300 | 20 | 31,60 | 24.998 |

| 650 | 250 | 290 | 20 | 38,14 | 30.578 |

| 820 | 250 | 290 | 20 | 48,42 | 37.819 |

Our production includes big tanks for the storage of high quantity of liquids, where it is not possible to place various products side by side. The tanks are ribbed with reinforced beams in order to garantee drive over.

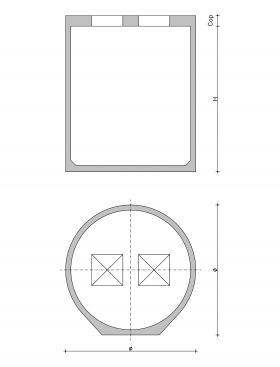

Cylindrical tanks

Tanks sizes

(standard production in cms)

| Ø | H | Cov. | S. Volume | Weight |

| (cu.m.) | (daN) | |||

| 170 | 200 | 15 | 3,50 | 3.507 |

| 170 | 250 | 15 | 4,43 | 4.015 |

| 170 | 300 | 15 | 5,36 | 4.525 |

| 250 | 200 | 20 | 7,81 | 7.735 |

| 250 | 250 | 20 | 9,89 | 8.747 |

| 250 | 300 | 20 | 11,96 | 9.759 |

N.B.: only Ø 250 tanks are complete of pedestal.

We garantee the perfect hydraulic tightness of our tanks, with no need of waterproof treatments.

Material specifications

Precast vibrated reinforced concrete tanks

For the production of the tanks the following materials are normally used:

CONCRETE

PORTLAND I 52,5R concrete

resistance class C 50/60

minimum concrete content 400 kg/cbm

sulfate resistant according to UNI9156

vibration in metal formworks with porosity and honeycomb elimination

S5 super fluidizer added

environment exposition class XC2 (according to UNI 206-1)

minimum bar cover 20 mm

REINFORCEMENTS

B450C steel tested in factory

deformed bars and electrowelded net

assembly with double reinforcement

On demand, other environment exposition classes can be used